INNOVATION

Pipetech are approached about a problem. This could range from: speeding up a process, allow operators to fix something without turning off gas/water supply, reduce excavation, cost, improve safety, etc.

PROBLEM

We meet with the client to discuss their requirements in depth and to further understand their problem.

DISCUSSION

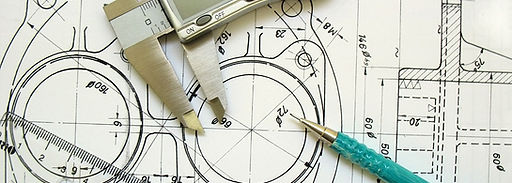

We begin the design process with our in-house design engineers, who collaboratively have over 150 years worth of experience in the industry, using the latest drawing technology.

DESIGN

Concept designs are reviewed with the customer. Following the engagement, options are selected for developing and trialing with an initial prototype made.

DEVELOP

Following feedback from the field trials, we modify and amend the design accordingly (if required). This is to ensure the product(s) are to the highest standard and meets the

exact specification.

MODIFY

Once the product has been approved, we produce and supply the equipment to the customer.

SUPPLY

-

CONCEPT TO INSTALLATION: Our R&D Department is available for in-house and sub-contract drawing projects, utilising the latest AutoCAD and inventor technology.

-

3D CAD MODELLING: We can produce individual components, assembly, bill of quantities, piping layout and isometric drawings. We model components in 3D prior to manufacture.

-

RAPID PROTOTYPING: The Pipetech R&D department has access to 3D printing which allows us to accelerate the design process with less cost for our customers.